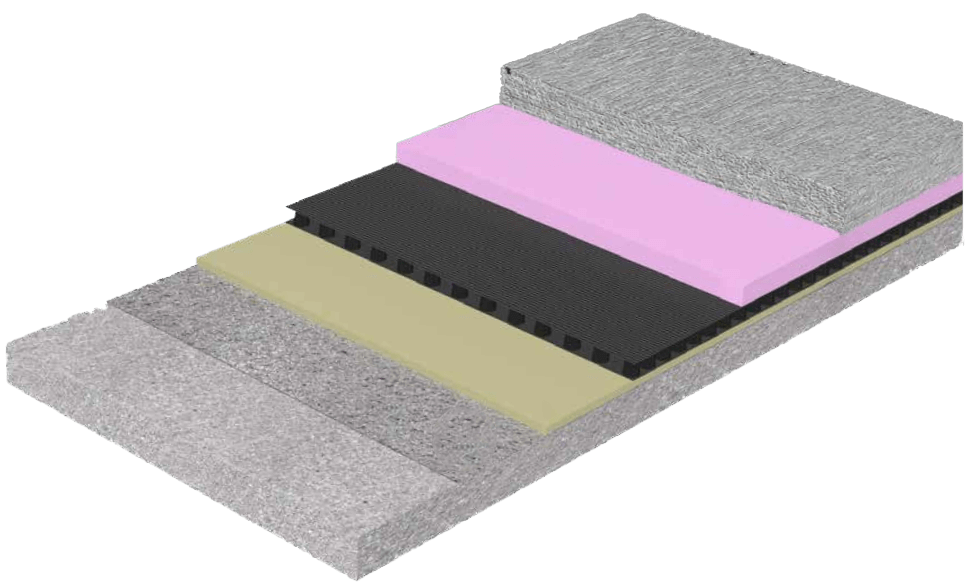

Horizontal (PUMA)

Brand: Tremco IncorporatedTREMproof® PUMA is a cold-applied, waterproofing system that utilizes polyurethane-methacrylate (PUMA) technology. PUMA waterproofing systems offer superior elongation over traditional MMA/PMMA technology systems. TREMproof PUMA is composed of a primer (Tremco PUMA Primer) and a base coat (Tremco PUMA BC or Tremco PUMA BC LM). All system components are cured using Tremco PUMA Initiator.

Features- PUMA technology delivers extreme durability while maintaining its crack-bridging characteristics, eliminating the need for reinforcing fabric

- 30 to 45-minute cure time between coats; ability to proceed to overburden 1 hour after application

- Can be applied at temperatures as low as 14 °F (-10 °C), which allows for continuation of projects in the colder months

- Zero Volatile Organic Compounds (VOCs)

- Compatible with Tremco sealants, coatings and expansion joints, which is essential for tie-ins, detailing and penetrations.

Specifications

Brand

VOC Content (Method 310)

- 0 g/L

% Solids (By Weight) (ASTM D1353)

- 100%

Drying Time @ 75°F, 50% RH (ASTM D1640)

- 80 mil film, 1 hr

Weathering (ASTM D822) Weatherometer (350 hr)

- N/A

Elongation (ASTM D638)

- 407-420%

Elongation (ASTM D5147)

- Min 30%

Tensile Strength (ASTM D638 @ 75°F)

- 991-1680 PSI

Tearing Resistance (ASTM D4073)

- 91 lbf

Hardness, Shore D (ASTM D2240)

- 18-35

Hardness, Shore A (ASTM D2240)

- 65-87

Abrasion Resistance (1000 Cycles) (ASTM D4060)

- N/A

Low-Temperature Crack Bridging (ASTM C1305)

- Passes

Taber Abrasion (ASTM C501)

- Passes

Peak Load @ 73°F, AVG (ASTM D5147)

- >70 lbf/in

Puncture Resistance (ASTM D5602)

- >56 lbs

Water Absorption (ASTM D570)

- <0.1%

Water Vapor Transmission (ASTM E96)

- 0.03 perms

Adhesion-In-Peel (ASTM C794)

- Concrete Failure with Primer

Self-Ignition Temperature (ASTM D1929)

- 800°F (427°C)

Smoke Density (ASTM D2843)

- 4.1%

Rate of Burn (ASTM D635)

- 1.2 in/min