Non-Load Bearing Connector (NLB)

Brand: FastenMasterThe NLB Fastening System is designed for connecting the top plate of non-load bearing walls to trusses or joists above. It allows for vertical movement of the trusses while providing lateral stability to the wall

Connection Details

- The top plate of non-load bearing walls must be connected at the top to resist the code-required lateral loading of 5 pounds per square foot of wall area

- A gap must be left between the wall and the truss or joist to allow for vertical movement due to live loads and seasonal changes

- If built without a gap, loads can be transferred onto these walls that could cause serviceability issues leading to callbacks

- Currently this type of gapped connection requires a clip that must be installed from above the plate and sometimes from both sides of the truss

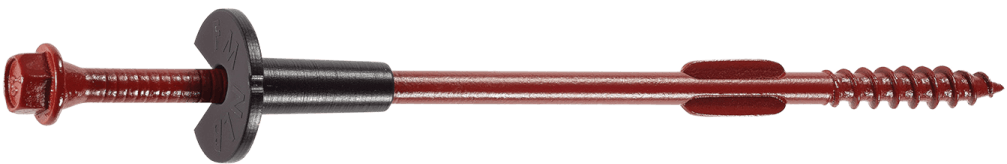

- A 6” hardened structural screw with sharp point and aggressive thread quickly pass through the plate and engages the truss during installation

- The specially designed cutting wings on the shank of the screw cut a hole in the top plate

- A pre-attached sleeve on the fastener fits into this hole, creating a friction-free guide that allows for vertical truss movement

- The NLB Setting Tool automatically sets the head ¾” proud for potential upward truss movement and ease inspectability

Safety & Productivity Benefits

- Replacing clips and nails means no pneumatic nail gun or hoses

- Installation from the floor surface eliminates the need for ladders or scaffolding

- Connections can be made up to 10x faster, significantly reducing labor

- Eliminating the need for double top plates on non-load bearing walls provides meaningful material savings on the overall project