Decorative Flashing System (PUMA)

Brand: Tremco IncorporatedTREMproof PUMA Decorative Flashing System is a quick-cure, liquid-applied system based on PUMA technology. Components of the system can be initiated to cure within minutes, even in temperatures below freezing, and has tenacious adhesion to concrete and metal.

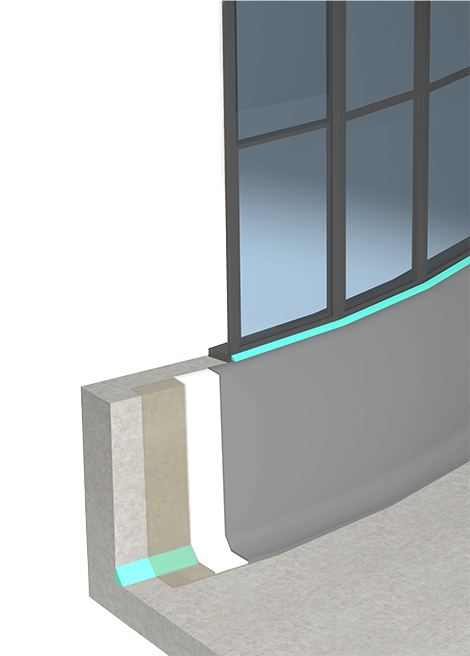

Features- TREMproof PUMA Decorative Flashing System is designed to be used as a replacement for stainless steel flashing.

- Potential applications include curb-to-curtain wall, curb-to-facade, deck-to-door, balcony slider doors, exposed window flashings and more.

- Polyurethane-methacrylate (PUMA) technology delivers extreme durability and crack-bridging capabilities at critical connection points.

- Significant labor savings vs. stainless steel flashing - no fabrication, bending, overlapping, soldering or open seams - and the ability to handle complex geometries with ease.

- Field-tintable and custom color paks to match EIFS, brick or other building façade materials

- Significant labor savings vs stainless steel flashing — no fabrication, bending, overlapping, soldering or open seams — and the ability to handle complex geometries with ease

- System warranties available to include seamless connections to adjacent building envelope components for single-source, warranted, tested systems

- PUMA technology delivers extreme durability and crack-bridging capabilities at critical connection points

- Can be applied at temperatures as low as 14 °F (-10 °C), which allows for continuation of projects in the colder months

- Zero Volatile Organic Compounds (VOCs)

- Compatible with Tremco sealants, coatings and expansion joints, which is essential for tie-ins, detailing and penetrations

Specifications

Brand

VOC Content (Method 310)

- 0 g/L

% Solids (By Weight) (ASTM D1353)

- 100%

Drying Time @ 75°F, 50% RH (ASTM D1640)

- PUMA Flashing - 80 mil film, 1 hr

- PUMA TC - 17 mil film, 1 hr

Weathering (ASTM D822) Weatherometer (350 hr)

- PUMA Flashing - N/A

- PUMA TC - 17 mil film, 1 hr

Elongation (ASTM D638)

- PUMA Flashing - 407-420%

- PUMA TC - 130%

Elongation (ASTM D5147)

- Min 30%

Tensile Strength (ASTM D638 @ 75°F)

- PUMA Flashing - 991-1680 PSI

- PUMA TC - 986 PSI

Tearing Resistance (ASTM D4073)

- PUMA Flashing - 91 lbf

- PUMA TC - 203 lbf

Hardness, Shore D (ASTM D2240)

- PUMA Flashing - 18-35

- PUMA TC - 55

Hardness, Shore A (ASTM D2240)

- PUMA TC - 100

- PUMA Flashing - 65-87

Abrasion Resistance (1000 Cycles) (ASTM D4060)

- PUMA TC - 51 mg

- PUMA Flashing - N/A

Low-Temperature Crack Bridging (ASTM C1305)

- PUMA TC - N/A

- PUMA Flashing - Passes

Taber Abrasion (ASTM C501)

- PUMA Flashing - Passes

- PUMA TC - N/A

Peak Load @ 73°F, AVG (ASTM D5147)

- PUMA Flashing - >70 lbf/in

- PUMA TC - 238 lb/in

Puncture Resistance (ASTM D5602)

- > 56 lbs

Water Absorption (ASTM D570)

- <0.1%

Water Vapor Transmission (ASTM E96)

- 0.03 perms

Adhesion-In-Peel (ASTM C794)

- PUMA Flashing - Concrete Failure with Primer

- PUMA TC - N/A

Self-Ignition Temperature (ASTM D1929)

- PUMA Flashing - 800°F (427°C)

- PUMA TC - 850°F (454°C)

Smoke Density (ASTM D2843)

- PUMA Flashing - 4.1%

- PUMA TC - 2.1%

Rate of Burn (ASTM D635)

- PUMA Flashing - 1.2 in/min

- PUMA TC - 0.2 in/min